Trim-A-Slab – The Best Solution for Concrete Expansion Joint and Sidewalk Caulk Expansion Joint Repair

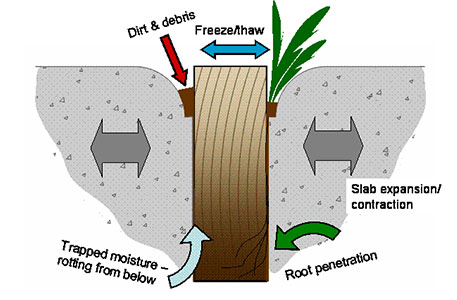

Are you looking for a solution for Sidewalk Caulk Expansion Joint repair? Trim-A-Slab is a replacement for rotted and old wood typically found between slabs in driveways and sidewalks. This wood was used during the slab construction, and is part of the ‘formwork’ used to define the size and shape of the slab. Once the cement had cured, it remained to accommodate movement of the slab as it is heated in summer and cooled in winter. This wood then functions as an ‘expansion joint’, but not very well.

The problem is that what makes good formwork does not necessarily make a good expansion joint. The elements conspire to attack and destroy the wood, even if it was a rot resistant variety or pressure-treated to resist rot. Moisture allows bacteria to attack and break it down, movements open gaps which allow dirt and roots in, and eventually, the formwork looks a lot more like potting soil than wood.

Unless treated with weed-killers, your driveway can easily look like the one pictured below. Of course, chemical weed-killers are also undesirable, as driveways are almost always very close to storm drains. The best way to keep chemicals out of your local watershed and fisheries is not to use them at all.

Trim-A-Slab

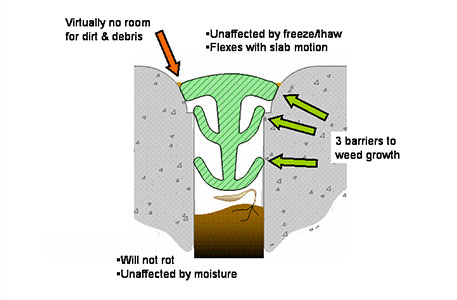

Trim-A-Slab is made from a rubber-like material that flexes and holds itself into the gap between concrete slabs. It is a good solution for concrete expansion joint repair. It is immune to rot, moves with slab expansion and contraction, and is not affected by moisture. It provides a redundant barrier to weed growth, and most importantly, does not trap dirt and debris like wood and other less flexible products. It will make your driveway easier to keep clean.

Trim-A-Slab is a patented design (US 8,132,380), and is intended for slabs with radius (rounded) edges, and will fit and stay just below the surface without any special preparation. The exposed surface is slightly recessed, and is resistant to damage from foot and auto traffic.

The clean, finished appearance is something your family and your neighbors will notice right away. You don’t have to take our word on it, our customer testimonials say it better than we can. It’s virtually maintenance free, and in case you need to run wires across your driveway for Christmas lights or an irrigation system, Trim-A-Slab can be removed and re-installed, no problem.

Trim-A-Slab is available in six sizes, 3/16″, 3/8″, 1/2″, 3/4″, 1″, and 1-3/8″. Trim-A-Slab sizes follow THE GAP THAT YOU ARE FILLING. Trim-a-slab comes in black, cement grey, or walnut. Choose black for the lowest maintenance or an accented appearance. Choose grey to blend in. Walnut goes well in stamped or stained driveways. Please note, Walnut and Grey will show tire marks after a while, but they clean up easily with soap and water. All are guaranteed for up to 10 years for structural integrity, so whichever look you prefer, you can be sure it will last.

Trim-A-Slab is available in pre-cut rolls, which weigh less than 20 pounds each, so if you do want to install yourself, it’s easy to handle. Visit the DIY installation page for all you need to know about installing Trim-A-Slab. If you aren’t the do-it-yourself type, visit the professional installation page for a list of installers, who will take care of the whole job for you.

Cost Comparison

When it comes to concrete expansion joint sidewalk caulk expansion joint repair, there are a few options to consider. You can replace the wood with new wood, replace it with caulk, or replace it with a filler strip. Of these options, wood is clearly the worst. It is the hardest to fit back into the space, and there is no easy way to secure it. Any warping tending to lift it out of the joint will create a protruding trip hazard. All the same problems explained above with new wood remain as well, so weeds will establish themselves in the cracks, and in a few years the process will have to be repeated.

The next thing to consider is the caulk-like repair. This method has more than a few issues as well. The material will fill the void space completely, which is good, but any subsequent caulk shrinkage or movement of the slab to open the joint will pull the caulk from the concrete and create a vertical crack. This crack then fills with dirt, debris, and finally weeds. The caulk-like fillers simply don’t have enough compliance (which is pure stretching) to fill an expanding gap.

These materials also must be installed with some planning and skill. The depth of the evacuated joint must be closely controlled in order to be able to correctly estimate the amount of stuff needed to fill the joint. This can be done by back-filling the joint with sand, or by installing a filler strip (backer rod) which is pushed down to the desired depth. The filler strip is fairly easy to use, but the finished expansion joint is actually poorly supported, and can collapse down into the joint over time or due to foot or wheeled traffic. Lastly, the caulk-based repairs are a viscous sticky liquid which must cure. This means it must be installed carefully, and in a controlled manner to get a nice end product. The following instructions are from a tube of name-brand concrete and mortar filler and sealant:

Apply in temperatures over 40 F

Do not apply when rain or freezing temperatures are forecast

Joint should not exceed 1/2 wide by 1/2 deep

Allow to cure for 24 hours before direct exposure to water

Completely dry in 7-14 days

These are a lot of restrictions, and in addition, if your driveway is sloped, the material will run downhill, and may be difficult to keep where you want it.

The best method is to re-fill the gap with a ‘compliant filler strip’; Trim-A-Slab. A compliant strip, which is compressed when installed, is able to expand back to a larger size when the slabs move away from each other. Neither wood nor caulk fillers can do this. The more compliant the strip, the greater the range of motion that the joint can have without becoming loose and allowing dirt and weeds to accumulate. Trim-A-Slab is very compliant, so much so that it takes only 6 sizes to fill gaps from 3/16″ wide (about half the diameter of a dime) all the way up to 1 and 5/8″ wide. This compliance also makes Trim-A-Slab incredibly easy to install. Most of the time, it can be installed by hand.

As you can see, Trim-A-Slab is a clear choice for families that lack time, tools, skill, and wish to save some money on a simple DIY project. Trim-A-Slab installs fast, about a foot per minute. A typical 2 car driveway with 100 ft of expansion joints is done in about an hour and a half. It will take about 37 tubes of caulk to do the same job! How many squeezes of the caulk gun is that?

If you need proficient Concrete Expansion Joint and Sidewalk Caulk Expansion Joint Repair solutions, contact our team at 281-724-0493 or [email protected].